work in process inventory definition

All materials waiting to be assembled Finished goods inventory. The value of that partially completed inventory is sometimes also called goods in process on the balance sheet particularly if the company is manufacturing tangible items rather than providing services.

One Of Our Customers Shared Their Inventory Management Process Workflow Of Gift Man Business Process Business Process Management Inventory Management Templates

6 rows Work in process inventory is generally described as a companys unfinished goods waiting to be.

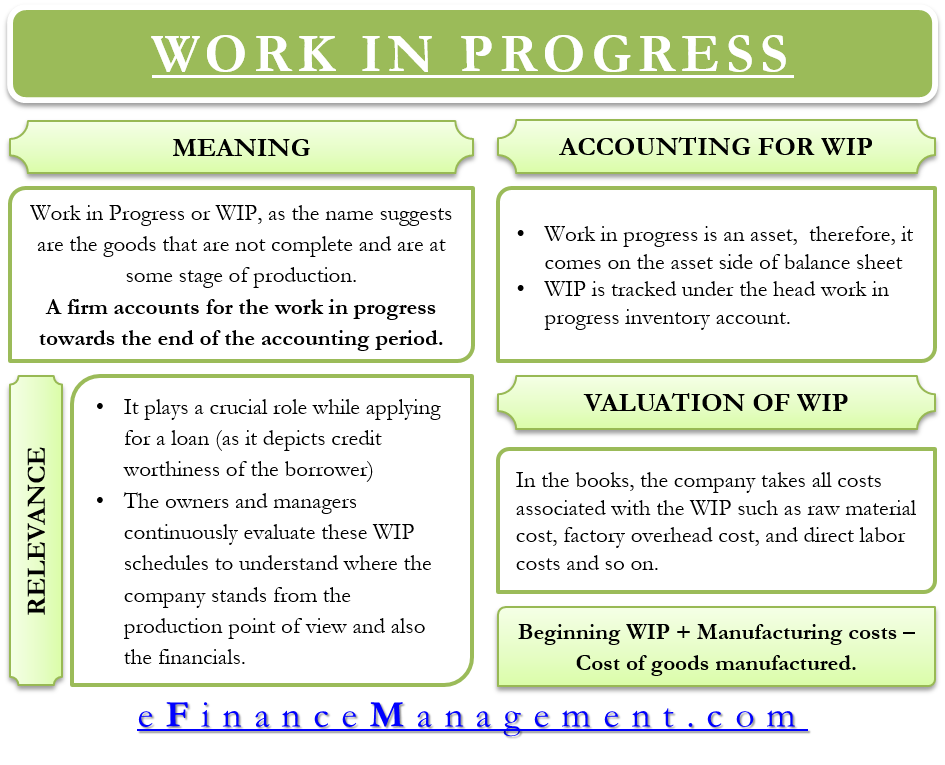

. These items are typically located in the production area though they could also be held to one side in a buffer storage area. What are the disclosures for a manufacturers inventory. WIP Inventory Work-in-Progress is defined as the goods which are in different stages of production.

Assembled materials ready to be sold. Work-in-process inventory is materials that have been partially completed through the production process. They may also be referred to as in-process inventory.

As the combs move from one department to another more costs are added to production. Why Is Work In Process Inventory Important. The work-in-process inventory account of a manufacturing company shows a balance of 3000 at the end of an accounting period.

In other words it includes the unfinished goods in the manufacturing process that are awaiting completion. Once the manufacturer starts the production process those items are no longer raw materials. The cost of work-in-process typically includes all of the raw material cost related to the final product since raw materials are usually.

They may be on a conveyor belt in the act of fabrication or they may be waiting in a queue. It is also termed as work-in-progress inventory. Sometimes the accounting system accounts for the semi-finished goods in this category.

As raw materials and components are consumed they gain value because they have incurred some labor and overhead. And each subsequent sub-process throughout the factory adds additional value. The term work-in-progress is a production and supply-chain management term describing partially finished goods awaiting.

Work in process WIP inventory refers to the total cost of unfinished goods currently in the production process at the end of each accounting period. Work-in-process inventory refers to the inventory created by raw materials that havent yet reached the finished goods stage. Work in Progress WIP Inventory includes material that has been released from the inventory for the process but not yet completed and is waiting for a final inspection.

Businesses who sell highly-customized products are more likely to have WIP. What is work-in-process inventory WIP. They reserve work in progress for larger-scale projects like consulting or construction work.

Work-in-process inventory refers to a material that is in the process of being produced or manufactured into complete goods to be sold to customers by a company. Some folks refer to work in process inventory only in the context of production operations that move along relatively quickly. Though some within supply chain management do make a small distinction between them.

Work-in-process WIP refers to a component of a companys inventory that is partially completed. WIP Work In Process Inventory is the total cost of unfinished goods currently in the production process. It is also considered a current asset on a companys balance sheet.

The work-in-process inventory account is the asset account that a company uses in order to record the value of its work-in-process. This figure is the ending work-in-process inventory for that quarter year or whichever accounting period. The work in process inventory refers to the part of the production cycle of turning your individual raw materials into a kettle.

Work in Process Inventory means the work undergoing a manufacturing process eg parts and subassemblies in the process of becoming completed assembly components or finished goods or the work undergoing a development process eg labor material and overhead accumulated toward customer milestones and released to finished goodscost of sales upon milestone. This account includes the accounting periods beginning value of. Another reason for work in process inventory is safety stock buffer stock or anticipation inventory.

Therefore the direct labour and the operational cost of putting the kettle together would be classified under work in process inventory. WIP or Work in Progress is a part of a companys overall inventory that has begun being processed but is not yet finished. When used in supply chain management work in process is associated with the total cost of unfinished goods that are currently in production.

In standard costing how is the purchase price variance reclassified to arrive at actual cost. The term work in process WIP inventory is widely spread and mainly used in the sphere of supply chain management. Work in process and work in progress WIP are inventory management terms that refer to partially-completed goods within any production round.

Anything needed to manufacture a product Work in process inventory. Work in process inventory and work in progress inventory are interchangeable phrases for the most part. WIP inventory is a vital production step that is considered an asset on a companys balance sheet.

It is considered a current asset on the companys balance sheet. Work in process inventory in the big picture Raw materials inventory. It relates to the overall costs of those goods that are non-finished yet or still in production.

The job-cost sheets of the two incomplete jobs show charges of 500 and 300 for direct materials. In supply-chain management work-in-progress WIP refers to goods that are partially completed. Manufacturers and other businesses that produce products are the only types of businesses that.

Work in process inventory is materials that are in the process of being produced or manufactured into finished goods to be sold to customers.

What Is Supply Chain Management Supply Chain Management Business Chain Management Supply Chain Management

Work In Progress Meaning Importance Accounting And More

Inventory Control System Inventory Accounting Control System Inventory

Lean Manufacturing Sixsigma The 7 1 Mudas Wastes For Office Manufacturing And Supply Cha Lean Manufacturing Lean Sigma Project Management Professional

Work In Process Inventory Formula Wip Inventory Definition

What Is Work In Process Wip Inventory Definition Formula And Benefits Article

Definition Of Annual Physical Inventory Open Source Erp Site Annual Physical Physics Cost Of Goods Sold

What Is Management Information System Features And Type Management Information Systems Management System

What Is Erp Visual Ly Erp System Business Software Enterprise Application

Best Iso Iec 27001 Implementatin Certification Services Certaim Com Risk Management Internal Audit Certificate

What Is Work In Progress Wip Finance Strategists

Types Of Inventory Stock Marketing Skills Learn Accounting Accounting And Finance

Timwood The Seven Wastes Of Lean Manufacturing Lean Manufacturing Lean Six Sigma Change Management

Wip Inventory Definition Examples Of Work In Progress Inventory

7 Elements Of Seamless Supply Chain Integration Supply Chain Logistics Supply Chain Supply Chain Management

Noob Guide To Supply Chain Management Definition Supply Chain Management Supply Chain Business Management Degree

What Is Work In Process Wip Inventory Definition Formula And Benefits Article

Work In Process Wip Inventory Youtube

Computer Integrated Manufacturing Cim Meaning Objectives And More Cost Accounting What Is Computer Accounting Principles